Dugagjin Berisha, a construction company owner and environment enthusiast, regularly organizes neighborhood clean-ups in his free time, hoping to teach local children the value of recycling and pollution prevention. But while sorting through everyday waste, he made a startling discovery – Kosovo had no means to recycle glass.

This realization ignited the journey of Kosovo Glass Recycling – at first by collecting glass waste in Berisha’s basement and then on a plot of land, generously provided by a family friend. Today, Kosovo Glass Recycling is the country’s only glass recycling company.

Berisha’s story is just one among a new generation of entrepreneurs rising to meet Kosovo’s environmental challenges. From recycling glass and creating edible cups to upcycling tires into furniture and digitizing waste reduction in manufacturing, these innovators are laying the groundwork for a greener, more sustainable economy.

A part of this transformation is UNDP’s BOOST, an acceleration programme for impact innovation, which has thus far organized two Kosovo Green Challenges to identify and amplify green business practices and solutions. Through the stories of five startups that participated, we’ll explore how Kosovo is tackling its waste management challenges head-on, one innovative solution at a time.

The Glass Revolution

“It wasn’t easy,” Martin, Berisha’s son, reflects, “but when you’re faced with a problem this big, you can’t just look away.” What began as a modest effort to prevent glass from becoming landfill waste is now evolving into a sustainable business model, backed by local and international investors. “We now collect about 10 tons of glass every day,” Martin reveals, highlighting the scale of their operation. Typically recycling 300,000 kilograms of glass annually, this year they aim to almost double their impact.

The company’s reach now extends beyond their hometown of Gjakovë/Đakovica. “We work with other towns around Gjakovë/Đakovica and have some collection points in the capital, Prishtinë/Priština,” Martin explains. Their efforts are making a dent in Kosovo’s glass waste problem, even without official national statistics.

Kosovo Glass Recycling’s impact is perhaps most visible in the hospitality industry. “We primarily work with hotels, restaurants, and cafés, which are the largest producers of glass waste,” Martin notes. They also collect industrial glass from companies that produce windows and flat glass, which generate a lot of broken material that waste management companies don’t handle.

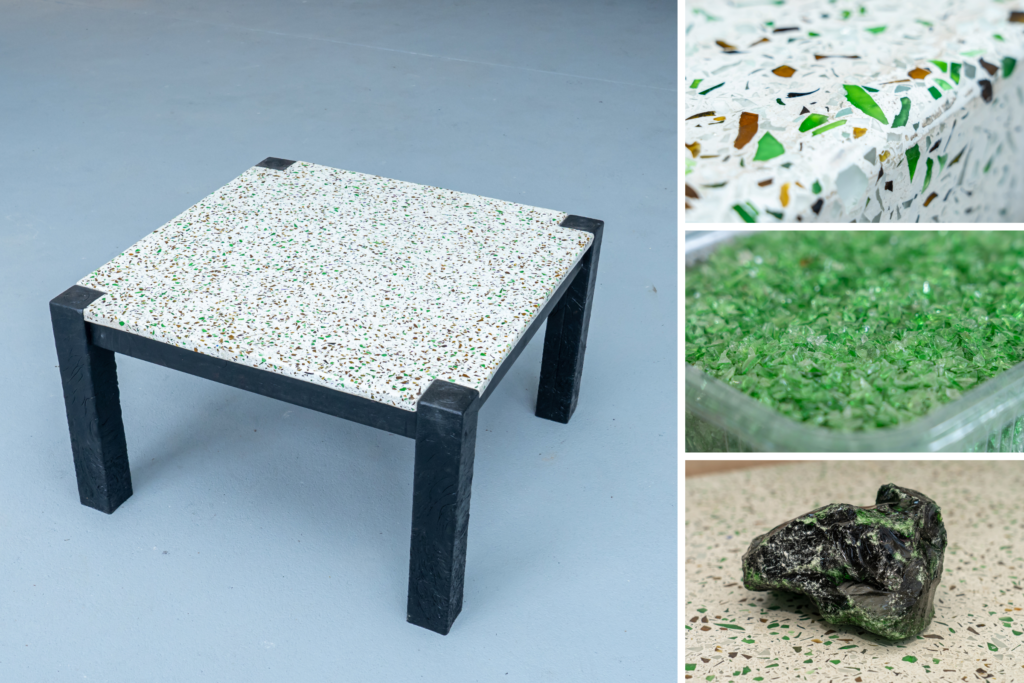

With the collected glass, they have created a range of innovative products that have found a ready market – from terrazzo-style tables and tiles to their most successful product – specialized pool filtration systems. “Every batch we produce is sold immediately,” Martin says. “Thanks to the BOOST programme, we also built a machine that crushes and sorts glass into different sizes, allowing us to make these specialized products.” But they collect more glass than they can repurpose, so they’re exploring opportunities to export recycled glass to larger companies in neighboring countries where it can be further processed.

Turning Tires into Treasures: Simply Green

While Kosovo Glass Recycling focuses on glass waste, Dorina Lluka Davies turned her attention to another environmental challenge: discarded tires. With a background in economics, psychology, and over 20 years in youth development, Davies was an unlikely candidate to revolutionize furniture making.

“I started looking at things differently, and I became deeply concerned about the environment after the birth of my twin boys,” Davies recalls. This concern led her to found Simply Green, a company that transforms waste tires into stylish, functional furniture.

The scale of the problem is staggering. “With about 500,000 to 600,000 cars in a population of 1.5 million, there are millions of tires being disposed of every few years,” Davies explains. In a country with no systematic tire recycling programme, this presents both an environmental challenge and an opportunity.

“But I had no experience in furniture building—I didn’t even know how to use a drill!” she admits. Undeterred, she set up shop in her father’s garage, experimenting with tires to create chairs. Through persistence and creativity, she developed a range of products, even trademarking one of her designs.

Today, Simply Green offers about ten different products, with 80-90% of materials being upcycled. “Besides tires, we also use wood from old kitchens or closets that people no longer need,” Davies explains.

For Davies, Simply Green isn’t only about creating eco-friendly furniture – it’s also about challenging gender norms in a male-dominated industry. “In Kosovo, out of a few hundred companies working with wood, only two are led by women,” she notes. By leading her company and actively participating in the production process, Davies is breaking new ground for women in Kosovo’s green economy.

As Simply Green continues to grow, producing up to 100 unique pieces a month, Davies is focused on scaling up production and raising awareness about the circular economy. Her participation in the BOOST programme has been instrumental, providing not just funding but also valuable mentorship and networking.

Edible Solutions: More Than Cup

In a world drowning in single-use plastics, another Kosovo-based startup is offering a solution you can literally sink your teeth into. More Than Cup, co-founded by Jeton Alshiqi and his team, is reimagining the way we think about disposable drinkware by creating cups you can eat after you’ve finished your beverage.

More Than Cup originated as a spin-off from a creative campaign developed by Jeton’s successful digital marketing agency. After a year of development and perfecting the product, More Than Cup launched its edible cups in 2023 made from natural ingredients like wheat, oat bran, and coconut oil. “They contain no artificial colors or flavors,” Jeton emphasizes. The environmental benefits are clear: “If someone can’t finish eating the cup after drinking their coffee, they can just leave it on the ground, and within two weeks, it will decompose naturally.”

The company’s dedication to sustainability goes beyond just the product. Even during production, imperfect cups aren’t wasted. “If a cup doesn’t pass our quality tests, we grind it up into biscuit crumbs, which can be used for making cakes,” Jeton explains.

More Than Cup’s approach quickly gained traction, not just in Kosovo but across the Balkans. “We now have teams in North Macedonia and Montenegro,” Jeton says proudly. The company is producing and selling about 15,000 cups per month across all locations.

What’s more, by June 2024, they had already saved significant amounts of plastic waste: 168 kilograms in Kosovo, 156 kilograms in Albania, and around 88 kilograms in Montenegro. “It’s a small but important step toward reducing plastic waste,” Jeton notes.

Participation in the BOOST programme proved pivotal for More Than Cup. With the help of a BOOST grant, they increased their production capacity by 200%, enabling expansion into neighboring countries, introduced a larger 200-milliliter cup to meet market demand, and established cooperation with another BOOST participant to supply ingredients. The programme also provided valuable mentorship, helping the team refine their business model and improve their pitching skills.

Digital Transformation for Sustainability: PNC

In the heart of Kosovo’s bustling furniture industry, a digital revolution is quietly taking place. PNC, founded by Andi Dragusha, is proving that sometimes the most powerful tools for reducing waste don’t come in the form of recycling bins or upcycled products, but in lines of code and smart algorithms.

“I started working with companies and organizations in Kosovo, providing training for machinery in the wood industry, and noticed a significant gap: while larger companies were investing in digital solutions to increase production and reduce waste, smaller businesses were being left behind,” explains Andi.

“Small and medium businesses weren’t viewing digitalization as a viable way to improve productivity or minimize waste,” Andi recalls. “Instead, they focused on investing in new machinery to achieve those goals.” This observation sparked an idea that would eventually become PNC.

Launched in mid-2021, PNC isn’t just another software company. It’s a bridge between outdated practices and modern efficiency, particularly for businesses relying on second-hand machinery from Europe. The impact of these digital solutions is tangible and significant. In the furniture manufacturing industry, waste is often measured in terms of yield – how efficiently a sheet of wood material is used. “Older algorithms typically result in 70-80% efficiency, whereas newer algorithms can achieve up to 90-97%,” Andi explains. This difference translates into substantial reductions in waste, which many companies in Kosovo currently discard. Their software solutions also help with better stock management, tracking material usage, and predicting waste, which helps companies optimize their resources.

Despite the clear benefits, convincing small and medium-sized businesses to adopt these digital solutions is a challenge. This is where the BOOST programme played a crucial role. “Through the BOOST programme, we provided free software to six companies,” Andi shares. This pilot programme allowed the companies to test the software to see its value in reducing waste and increasing efficiency.

By helping the furniture industry – one of Kosovo’s significant export sectors – become more efficient and sustainable, PNC is contributing to the overall competitiveness and environmental footprint of Kosovo’s economy. They are now exploring expansion into the metal industry to bring the benefits of digital waste reduction to an even broader range of industries in Kosovo.

Bio365 Kosova: From Farm Waste to Energy Bars

In the suburbs of Prishtinë/Priština, a unique venture is bridging the gap between sustainable agriculture and innovative waste management. Bio365 Kosova, founded by Emine Daci Zejnullahi, is not just producing organic products – it’s changing how agricultural waste is perceived and utilized.

Emine’s journey to eco-entrepreneurship is as organic as her products. “My background is in agriculture, and I work as a professor at the University for Business and Technology,” she explains. “I started this company several years ago out of a passion to support others by creating a small business.” This passion, rooted in a desire to produce healthy, pesticide-free products, has blossomed into a multifaceted enterprise that’s changing lives and reducing waste.

At the heart of Bio365 Kosova is a network of 15 women farmers from rural areas. “Many of these women were not previously working, but they owned land,” Emine says. Her company provided training in organic farming techniques, focusing on aromatic and medicinal plants. “We trained them, monitored their progress, and it’s been incredibly rewarding to see them succeed,” she adds, highlighting the social impact of her business model.

Bio365 Kosova specializes in essential oils and cold-pressed plant oils, including walnut and linseed oil. However, it’s their innovative approach to waste management that sets them apart. “During the processing phase, we realized we were losing a lot of valuable nutrients in the waste,” Emine recalls. So why not use this nutrient-rich waste to create something new they asked themselves?

The result? Energy bars made from the waste left over from cold-pressing oils. “We use all the waste from the cold-press process and add a few other ingredients, like coconut oil, to enhance the flavor and texture,” Emine explains.

Emine is also actively researching bio-waste in Kosovo’s food sector, aiming to raise awareness about its possible applications. “Many food companies are not recycling or utilizing their waste, but there is so much potential,” she says. “Whether it’s composting, making animal feed, or producing fertilizers, there are many ways to turn waste into something valuable.”

The BOOST programme has been instrumental in Bio365 Kosova’s growth. With the support from BOOST, the company purchased machinery to create the energy bars and employ more people. “The BOOST programme supported us a lot, not just financially, but through training and mentoring to conceptualize the new products we can create from waste,” Emine reflects. Emine envisions a future where waste is seen as a valuable resource rather than a problem to be disposed of, creating a model that’s good for people, profit, and the planet.

Paving the Way Forward for a Circular Economy

As Kosovo aligns itself with EU environmental standards and the Green Agenda for the Western Balkans, the landscape, however, is fraught with challenges. Kosovo’s undeveloped waste management infrastructure, limited government support, and the scarcity of reliable data on waste generation and recycling rates further complicates effective planning and policy-making.

In this challenging environment, support programmes like UNDP’s BOOST have proven crucial. BOOST provides not just financial support, but also mentorship, networking opportunities, and visibility. It has enabled companies like PNC to run pilot programmes, helped More Than Cup increase production capacity, and provided vital business skills to startups like Simply Green. These stories underscore the importance of not only comprehensive support programmes but also education and awareness-raising campaigns on the circular economy, increased government support through favorable policies and infrastructure development, cross-sector collaboration to spark new solutions, and embracing digital transformation.

In the face of global environmental challenges, Kosovo’s circular economy innovators are proving that with creativity, determination, and the right support, significant change is possible – a glimpse into a future where waste is not just managed, but transformed into opportunity.

*References to Kosovo shall be understood to be in the context of United Nations Security Council resolution 1244 (1999).